Introduction to maintenance tools

These tools will improve the maintenance quality of your Nittoku machines. Please contact your closest office for inquiries.

Network

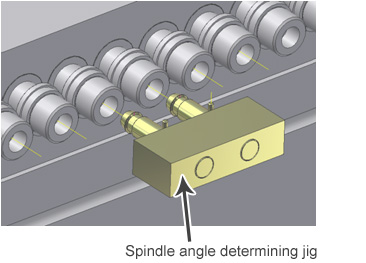

Spindle angle positioning jig

【Features】

This device can be used to adjust the angle of ajig holder that becomes misaligned due to regular maintenance work or failure.

The distance between shafts of spindle can be 20, 30, 40, 60, or 80mm.

This device allows you to make adjustments rapidly. To increase precision, please use the jig holder angle adjustment jig.

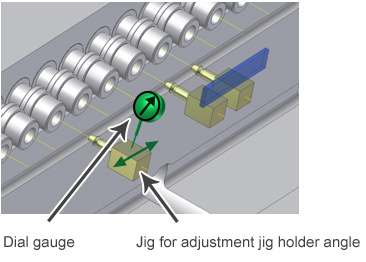

Jig for adjustment jig holder angle

【Features】

By using this part for adjustment of the angle of the jig holder, it is possible to confirm or adjust the angle of the jig holder with a dial gauge.

The spindle angle alignment jig can help reducing working time.

Using the two tools together, you can check the angle very easily.

(Optional: dial gauge)

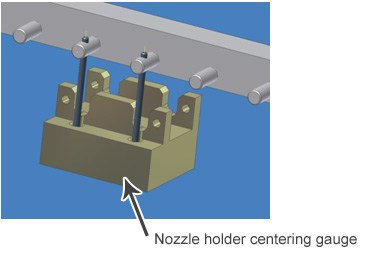

Nozzle holder centering gauge

【Features】

Allow each check/adjustment of in/out or angle of nozzle holder.

The distance between shafts of spindle can be 20, 30, 40, 60, or 80mm.

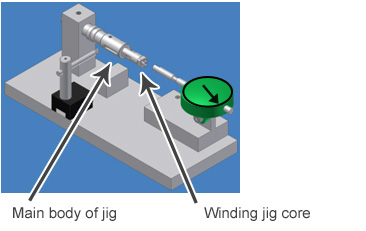

Winding jig core assembling base

【Features】

For assembling the main body and the core of winding jig.

Allow precise matching of the in-out size and installation angle of the main body of jig.

(The main body of jig and core are not included)

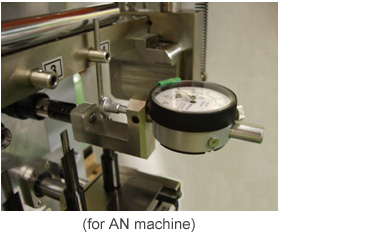

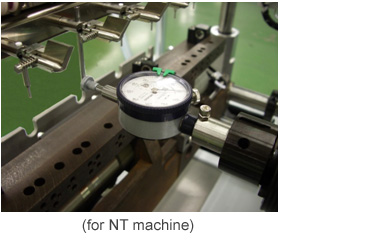

Nozzle in/out check gauge

【Features】

Necessary for AN・NT machine’s maintenance and for maintaining high quality of production to check nozzle in/out side.

Use [Nozzle in/out checking gauge] can make the checking easy and also can get highly accurate measurement.

Can help to keep consistent and high quality winding.

【HOW TO USE】

One-touch type.

Only need to put the gauge into tooling holder.

Put the [Nozzle in/out checking gauge] into the tooling holder, then only need to check the dia gauge.